the brinell hardness test of metals|brinell hardness testing method : manufacturer Brinell hardness is a unit of measurement that indicates the hardness of a material. It is measured using the Brinell hardness method, for which a hardmetal ball is pressed into the material. The size of the resulting . Resultado da Camará Shopping. Segunda a Sexta: LOJAS SATÉLITES, QUIOSQUES E ÂNCORAS: 10H às 22H CAIXA ECONOMICA FEDERAL: 10H às 15H LOTÉRICA: 09H às 20H . CINEMA: PROGRAMAÇÃO PRÓPRIA. Busca. Horários. Segunda a Sexta: LOJAS SATÉLITES, QUIOSQUES E .

{plog:ftitle_list}

web19 de jan. de 2024 · As apostas LoL - League of Legends têm vindo a ganhar popularidade no Brasil. Descubra os melhores sites de apostas LoL e como ganhar com CS:GO ou Dota 2. Casas de Apostas Cassino Poker . Então, listamos alguns dos melhores, analisando os odds, os torneios, os mercados e até os bônus para apostas LoL no Brasil. BÔNUS. R$ .

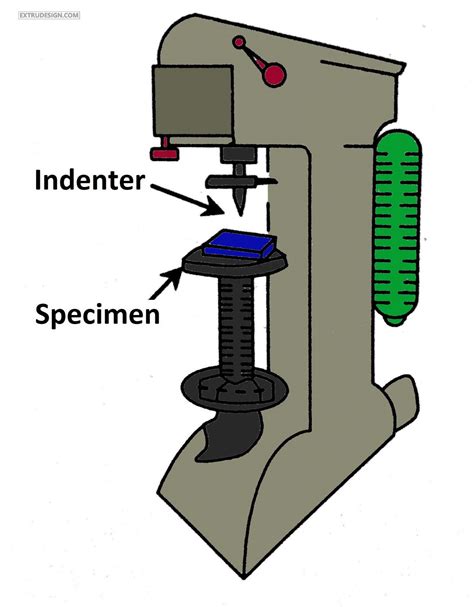

The Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the .

Brinell hardness is a unit of measurement that indicates the hardness of a material. It is measured using the Brinell hardness method, for which a hardmetal ball is pressed into the material. The size of the resulting . 1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the . The standard-compliant specification of Brinell hardness consists of the hardness value (HBW), the ball diameter (in millimeters), the test force (in kiloponds) and the application time (in seconds). These values are given .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, . As defined in ASTM E10-23, a Brinell hardness test is: “an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with diameter D), .

The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing .

The Brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (ISO 6506, ASTM E10). The Brinell method has a . 4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

brinell hardness testing procedure

mac tools c125 compression tester

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .In Johan August Brinell .Swedish metallurgist who devised the Brinell hardness test, a rapid, nondestructive means of determining the hardness of metals. Read More; materials testing. In materials testing: Hardness testing .a hardened steel ball (Brinell test) or a steel or diamond cone (Rockwell test) into the surface of the test piece.

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings. Brinell testing often use a very high test load (3000 .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the indentation is then . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation.

mac tools compression test kit ct115

Brinell Hardness Test Equations, Calculators and Review . The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is measured and a Brinell hardness number is calculated from this diameter. 4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.

Steel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . In industry, hardness tests on metals are used mainly as a check on the quality and uniformity of metals .

Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal .The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. . The .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .

The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. . Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum. 75 HB .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. . Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi .Common indentation hardness scales are Brinell, Rockwell and Vickers. See also: Hardness. Brinell Hardness Number – Brinell Scale. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal .Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings.

Brinell Hardness Test. The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter. The Brinell hardness number, or simply .

The Brinell hardness testing uses a 10mm hardened steel ball, while the Rockwell test uses either a much smaller steel ball (<4mm) or a diamond cone, depending on the material being tested. The Rockwell test measure the depth of the indentation, while the Brinell test measures the width of the indentation.

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .

3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with diameter D), . materials. 4.2 Brinell hardness tests are considered satisfactory for acceptance testing of commercial shipments, and have been To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. This process will result in the formation of a spherical indentation, and the load value per unit area of the indentation is considered as the Brinell hardness of the .

The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. . EN ISO 6506-1 is a European standard that specifies the requirements for metallic materials' Brinell hardness testing. It outlines the testing method, equipment, calibration, and .

brinell hardness testing method

mac tools compression test kit ct70

A TRANS ATILA – Transportes e Armazenagens é uma empresa que atua no segmento de transportes de cargas rodoviárias, com uma estrutura em constante evolução para atender às necessidades de Distribuição e Logística mais exigentes do mercado.. Contamos com profissionais devidamente qualificados, que atuam no seguimento há mais de 10 anos, .

the brinell hardness test of metals|brinell hardness testing method